Chapter 6 - Shaping A Greener Future With Science And Technology

As Singapore grapples with climate change and mounting waste, we are investing in research and development (R&D) and collaborating with industry experts to develop new, more efficient and eco-friendly ways to support the circular economy approach by recovering resources from waste.

Be it using microbes to convert food waste into compost, or turning incineration ash into construction materials – these are just two of the many possible ways to close our waste and resource loops through recycling or reuse.

These innovations came about because we have been experimenting with cuttingedge science and technology for more sustainable solutions.

For instance, R&D enabled the creation of Semakau Landfill, the first offshore landfill of its kind in the world, and Tuas Nexus – the first Waste-to-Energy incineration plant co-located with a water treatment facility to reap synergies.

As we face increasingly pressing and complex environmental issues, it is not enough to rely solely on our current expertise and infrastructure, or shape greener behaviour with policies and regulations alone. We will continue focusing on R&D to create and refine new technologies, products or systems that we can use and eventually share with others. In the coming years, we hope to pioneer transformative ways to enable Singapore to maximise our resource use.

Overcoming challenges and creating opportunities, together

Developing cutting-edge technologies requires collective effort, bringing together the expertise and resources of academia, enterprise and Government. Each has an important role to play.

- Academia from Institutes of Higher Learning (IHLs), Research Institutes (RIs) and polytechnics contribute deep scientific knowledge, scholarship, and know-how to turn theoretical concepts into potential solutions

- Enterprises provide market experience and ideas, and in some instances, financial resources or manpower. They are crucial partners for test-bedding R&D outcomes, scaling up solutions, and translating them into commercially viable applications

- The Government helps nurture and grow a thriving ecosystem, catalysing R&D by providing infrastructure, funding support, policy guidance, platforms for collaboration, and test-bedding opportunities

Having a cohesive R&D ecosystem helps turn ideas into commercially viable solutions. This goes from envisioning and theorising the best scientific approach to a given problem, testing it in a laboratory, to piloting it under real life conditions. Eventually, we will have a marketready solution.

This approach benefits all parties. Academics can see their ideas translated into real-life applications, while enterprises gain new business opportunities. All these boost economic growth and create highly-skilled jobs.

Our solutions could help other cities and regions too, and position Singapore as a global leader and centre of excellence in waste management and circular economy solutions.

CROSS-BORDER PARTNERSHIPS YIELD GREENER E-WASTE RECYCLING METHODS

From extracting gold, silver and other precious or strategic metals from printed circuit boards without using harmful pollutants, to creating greener chemical processes to recover materials from laptop batteries – these are just two tracks of R&D that the Nanyang Technological University (NTU) Singapore-CEA Alliance for Research in Circular Economy (SCARCE) will focus on to develop less energyintensive and more eco-friendly methods to treat and recycle e-waste.

SCARCE is a research centre that the French Alternative Energies and Atomic Energy Commission (CEA), a renowned multidisciplinary research centre in Europe, has set up together with NTU, and is CEA’s first joint laboratory outside France. It is also the first and largest single recipient of funding under the NEA’s Closing the Waste Loop R&D Initiative, with the NEA committing $12.5 million towards this $20 million centre.

One of its research projects is to develop eco-friendly methods of recycling lithium ion batteries commonly used in laptops, mobile phones and tablets. The goal is to extract up to 75% of the useful metals by weight, like cobalt, nickel and lithium, from used batteries. These can then be reused to produce new batteries.

Another project will look at extracting valuable metals from printed circuit boards, which are thin copper-plated or etched circuitry boards that mount integrated chips and electronic components in electronic equipment and appliances. The target is to develop novel methods to separate and recover metals, organics and ceramics from these discarded boards.

Local companies like Virogreen (Singapore) Pte Ltd have plans to collaborate with SCARCE, while TES-AMM (Singapore) Pte Ltd has expressed interest in industrial-scale pilot testing, to take the developed technology from the lab to the industry.

Our R&D investments to achieve zero waste

To improve technologies and solutions for recovering resources from waste, and come up with new ways to do the job, the NEA has established two key R&D programmes.

CLOSING THE WASTE LOOP

Launched in December 2017, the Closing the Waste Loop (CTWL) R&D Initiative is a $45 million programme that has funded eight projects worth almost $20 million as of 2019. The programme has three objectives:

- Resource efficiency – Develop ways to utilise resources efficiently and for as long as feasible. This includes better waste segregation, both at source and after disposal, which will maximise material and value recovery from waste. This ensures waste management processes are manpower, energy and water efficient.

- Landfill avoidance – Convert residues and waste (i.e. incineration bottom ash, incineration fly ash and non-incinerable waste) currently discarded at Semakau Landfill into useful resources, to extend the landfill’s lifespan beyond 2035.

- Maintaining high standards of public health – Besides protecting the environment, waste management (i.e. collection, recycling, disposal and treatment of waste) should be carried out in a safe and hygienic manner to maintain high public health standards.

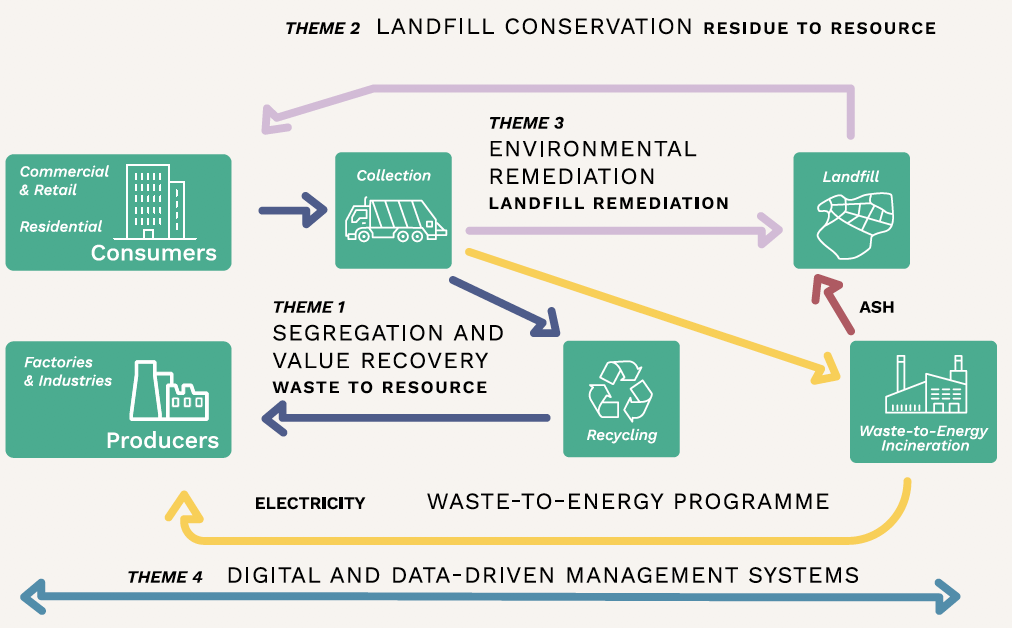

The CTWL initiative was developed with collaboration in mind, to encourage partnerships between IHLs, RIs and private sector enterprises. These stakeholders were consulted to develop the four themes under the CTWL initiative, which goes hand in hand with the Waste-to-Energy Programme, to maximise the use of resources at every opportunity.

Eight projects worth almost $20 million have been awarded under the CTWL initiative so far, and we will call for more projects in the near future. We will work with industry and research stakeholders to identify new focus areas of research.

THEME 1 Segregation and value recovery

Large amounts of leftover food, packaging waste and discarded electrical and electronic devices still end up at incineration plants today. We want to increase the recovery rate of valuable, usable materials from these key waste streams, and lower the economic cost and environmental impact of current recycling processes.

A NEW LEASE OF LIFE FOR PACKAGING WASTE

With no commercially viable way of recovering plastic layers found in most of the food, beverage and pharmaceutical packaging today, these materials are currently just incinerated.

But scientists are now trying to break the code to recycle these plastic-embedded multilayer films (MLFs).

A team from A-STAR’s Institute of Chemical and Engineering Sciences is developing a chemical recycling method that can separate and individually recycle the different polymer layers from MLFs. This makes it possible to extract valuable, pure components that can then be reused multiple times.

If successful, this chemical process could also remove additives like colour pigments and soluble polymers commonly found in plastic goods.

THEME 2 Landfill conservation

Just as PUB reclaimed used water to develop NEWater, the NEA is studying how to produce “NEWSand”: an environmentally sustainable product made from incineration ash that can be commercialised. Finding ways to use incineration ash, as well as non-incinerable waste and industrial residues, will not only extend the lifespan of our only landfill but also avail Singapore of a new source of construction materials.

As ash contains heavy metals, strict standards are being developed to allow NEWSand to be used in non-structural concrete, road base and sub-base. This is in view of the fact that much of land-scarce Singapore has been or will be designated as water catchments. Treated incineration ash that meets these standards will be allowed for unrestricted use in both moulded and unmoulded forms, without polluting our water resources. The standards will be validated through a demonstration project for incineration ash treatment, and a field trial for treated ash. The Land Transport Authority has identified a suitable site for field trials, in which treated ash will be used to lay the road base and sub-base layers. Groundwater samples will be collected and tested for changes in environmental characteristics and compared against samples of groundwater from a nearby control site made from conventional road building materials.

The design and results of the field trial will be reviewed by a Technical Expert Panel comprising experts in toxicology, public health, environmental health, incineration ash treatment methods, civil engineering, and hydrogeology.

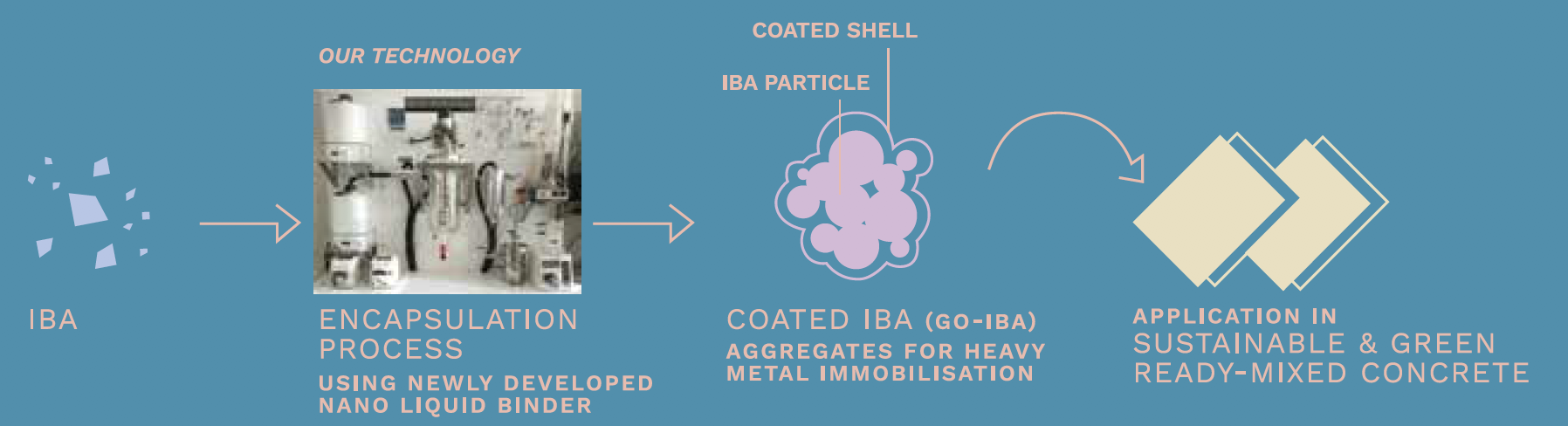

FROM ASH TO CONSTRUCTION MATERIALS

In the future, ash left behind from burning incinerable waste could be used to build our infrastructure.

Researchers from Republic Polytechnic are developing a solution to turn incineration bottom ash (IBA) into construction aggregates that can be added to produce ready-mixed concrete.

Their goal is not only to divert IBA from landfilling, but also address rising market demand for high quality aggregates. They believe their product could be a sustainable substitute for mined aggregates on the market.

THEME 3 Environmental remediation

Where trash from around the island once accumulated, we believe our past landfills can be rehabilitated and turned into reusable land for future development. Therefore, one of the focus areas under the CTWL initiative is to investigate and characterise these closed landfill sites, and use them as test-beds for technologies and techniques that could make them usable land again.

THEME 4 Digital and data-driven management systems

There is a need for systems to help monitor and assess the effectiveness of the initiatives we implement across the entire waste management value chain. We want to harness Information and Communications Technology (ICT), such as data analytics, to inform policy formulation and infrastructure planning in waste management and resource recycling.

WASTE-TO-ENERGY

Even as we try to maximise material resource recovery from our waste, Waste-to-Energy (WTE) remains a key strategy to extract value from residual waste that cannot be effectively reused or recycled. It also harnesses the energy content to produce electrical energy, while reducing the volume of residual waste and prolonging the lifespan of our precious Semakau Landfill.

To build up Singapore’s capabilities in energy and value recovery from waste, the NEA launched the $25 million WTE R&D programme in 2014.

The programme has two aims.

AIM 1 - Boost energy recovery efficiency of WTE processes and methods

Today, Singapore’s WTE plants are not only energy self-sufficient, but in fact supply excess electricity to the national grid. Finding more efficient WTE incineration processes with higher electricity output will help them meet a greater share of Singapore’s energy needs.

For example, one approach is to use oxygenenriched air. A team from NTU’s Nanyang Environment and Water Research Institute’s (NEWRI) Singapore Membrane Technology Centre is developing membranes that can efficiently produce oxygen-enriched air. They are also modelling the feasibility of using the membranes to enhance the current incineration processes. The challenge lies in extracting oxygen molecules from the air in a cost-effective and energy-efficient manner.

AIM 2 Explore alternative WTE technologies

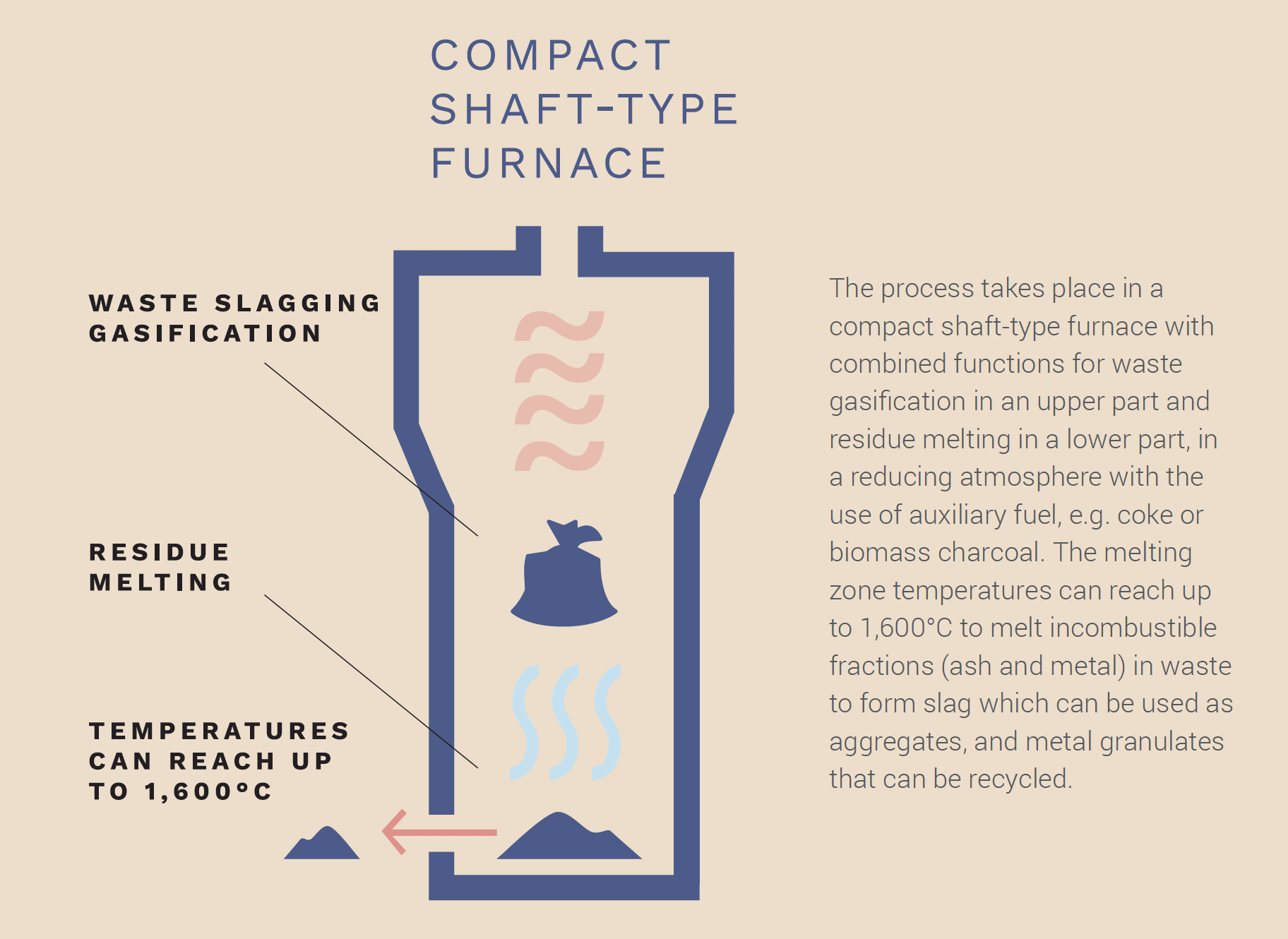

Alternative WTE technologies like gasification provide more renewable energy options and/ or higher value products from waste with minimal waste residues.

The WTE R&D programme aims to develop alternative, novel methods suited to our local context. For instance, Singapore’s municipal solid waste streams are highly heterogeneous and have high moisture content. Therefore, foreign technologies may not be immediately applicable in our situation.

By understanding our solid waste composition, we will be better able to generate useful by-products like better quality syngas, while increasing the amount of energy and resources recovered.

However, testing prototypes at existing WTE facilities is not feasible due to the disruption it would cause; neither are the facilities designed to accommodate such trials. Recognising this problem, the NEA contributed $12 million to co-fund the construction of a WTE Research Facility (WTERF) with NTU’s NEWRI. The Residues and Resource Reclamation Centre of NEWRI was tasked with the execution and project management of the WTERF construction and operation.

The $40 million WTERF provides local researchers and industry players with a physical, open platform for pilot testing. Its plug-and-play features support experimentation and test-bedding at scale, bridging the gap between laboratory research and commercial deployment.

The WTERF is the first of its kind in Singapore, employing high temperature slagging gasification as its underlying technology, and was officially opened in May 2019.

HOW DOES SLAGGING GASIFICATION WORK?

Charting our next R&D steps

Even as new technologies emerge from the CTWL R&D Initiative and WTE R&D programme, we must think ahead and identify new areas to study next. Only then can we remain at the forefront of science and technology.

We will look at how science and technology can help us create circular, sustainable systems of production, consumption, and waste and resource management within our economy.

Our key objectives are to:

- Develop viable substitutes for conventional materials

- Develop scalable technologies to separate waste into its constituents and turn them into resources and energy at lower economic and environmental costs

- Generate new, viable applications for resources generated from waste

- Integrate waste and resource streams systematically

With these principles in mind, research areas relevant to Singapore include:

SUSTAINABLE MATERIAL SUBSTITUTES

Inventing easily recyclable substitutes to commonly used materials will make recycling and upcycling of waste cheaper and more convenient. This could be in the form of specially formulated non-metal nanostructures (made of paper, for example) that could replace metal electronic circuits and wiring.

NEW APPLICATIONS FOR RESOURCES HARVESTED FROM WASTE

One promising area is nutraceutical extraction, which involves extracting valuable substances with medical or health benefits from food waste.

Through research, we can identify useful substances within common types of food waste, and develop techniques to hygienically and efficiently extract and convert them into products fit for human consumption.

For instance, bioactive compounds can be extracted from vegetable and food wastes, such as skins, stems, seeds, and residues from oils, juices and sugar extraction. These compounds can then be turned into high value nutraceuticals and functional foods like health supplements and food additives.

INTEGRATING WASTE AND RESOURCE STREAMS

Industrial symbiosis is a form of brokering, where companies are brought together in mutually profitable transactions. This involves finding ways to use the waste from one company as raw materials for another.

Research in this field explores better ways of converting waste from one industry into usable materials for another, or discovering new, industrial-scale uses for existing waste streams currently not recycled or reused.

Increasingly, we are focusing on the foodwater- waste-energy nexus, to find ways each sector can benefit from the other. This includes extracting nutrients from our waste for use in fertilisers in agriculture and horticulture.

By test-bedding such synergistic innovations at scale, we hope to translate these into real, commercially viable solutions.

Going forward, there will be ample opportunities to pilot circular zero waste solutions suited for local conditions, and integrate them with other systems to maximise district-level synergies.

Integrating these solutions into future housing estates and town centres will show how R&D helps fashion our living spaces into places where we can live and work in a sustainable, eco-friendly fashion.

Our R&D journey continues

By working closely with academia and industry, we will guide our R&D efforts to create economic opportunities for our companies and jobs for our people.

In this way, we can successfully adopt a circular economy approach to fulfil our vision of a Zero Waste Nation where Singaporeans can thrive and prosper.

https://www.towardszerowaste.sg/zero-waste-masterplan/chapter6/