Chapter 5 - Transforming The Environmental Services Industry

From the adoption of technology to making cleaning and waste management jobs smarter, safer and easier, to helping local companies go global – the environmental services industry is getting a facelift to sparkle with higher productivity and capabilities.

They keep roads, housing estates, schools and offices clean. But the labour-intensive Environmental Services (ES) industry suffers from an image problem. The industry, comprising 1,280 licensed cleaning firms, 450 waste management companies and over 300 pest management companies, is often viewed as low-skilled and low-tech, and overlooked by young job seekers due to the lack of career prospects.

But that will soon change. With the adoption of a circular economy approach in waste and resource management, we will require the support of relevant enterprises and a skilled workforce. This will require the ES industry to become sleeker and more sophisticated with a makeover.

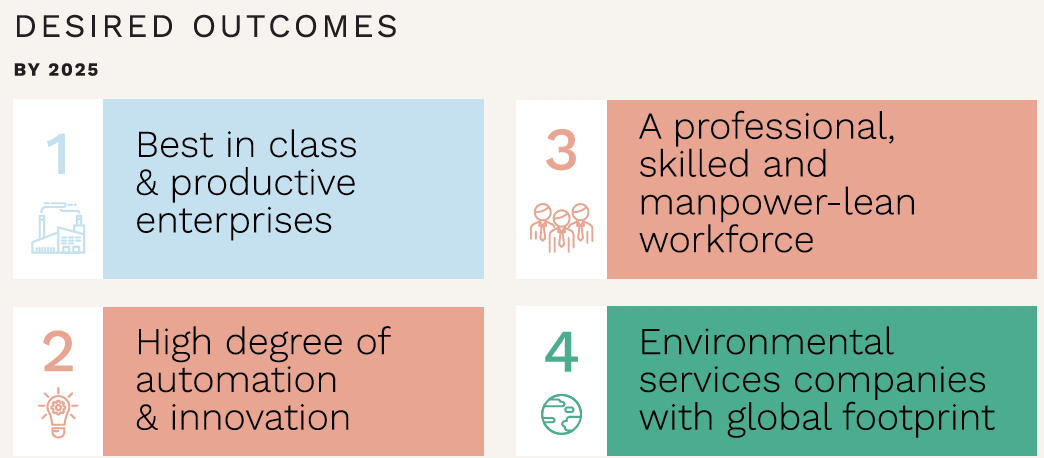

This is the aim of the Environmental Services Industry Transformation Map (ES ITM), which focuses on four main areas: technology and innovation, jobs and skills, productivity and standards, and internationalisation. These areas will be supported by enablers.

By 2025, we expect about 30,000 people from the industry to benefit from higher-value jobs through skills upgrading and technology adoption.

ITM FOCUS 1: Technology and innovation

By ramping up the use of technology, the industry will find innovative ways to get the job done with less sweat – raising the productivity of all employees. This will also create new and more highly-skilled jobs that will attract younger Singaporeans to join the industry. Ultimately, we hope to export these technologies overseas.

Here are two strategies to achieve this target:

STRATEGY 1 SPUR INNOVATION

There are four approaches to drive the development of new technologies and solutions:

- Develop new ways to perform cleaning and waste management tasks that can be scalable and replicated overseas

- Help companies expand their capabilities and grow by providing opportunities to expand their businesses in global markets

- Promote research and development (R&D) within companies

- Position Singapore as the technology centre of excellence by showcasing locally developed cleaning and waste management solutions, and nurturing companies which innovate

Instead of relying heavily on manual labour, Singapore aims to automate waste management processes, including waste collection and the sorting of recyclables. Doing so will make the industry less labourintensive, enable workers to take on more complex tasks and improve overall efficiency.

To encourage Singapore companies to develop novel ES solutions that can cut our manpower needs, bring about cost savings, and improve the quality of operations, the NEA and Enterprise Singapore launched the Gov-PACT innovation calls. The opportunity to supply such solutions to the Government will help our local enterprises build innovation capabilities and track records when scaling up locally or exporting overseas.

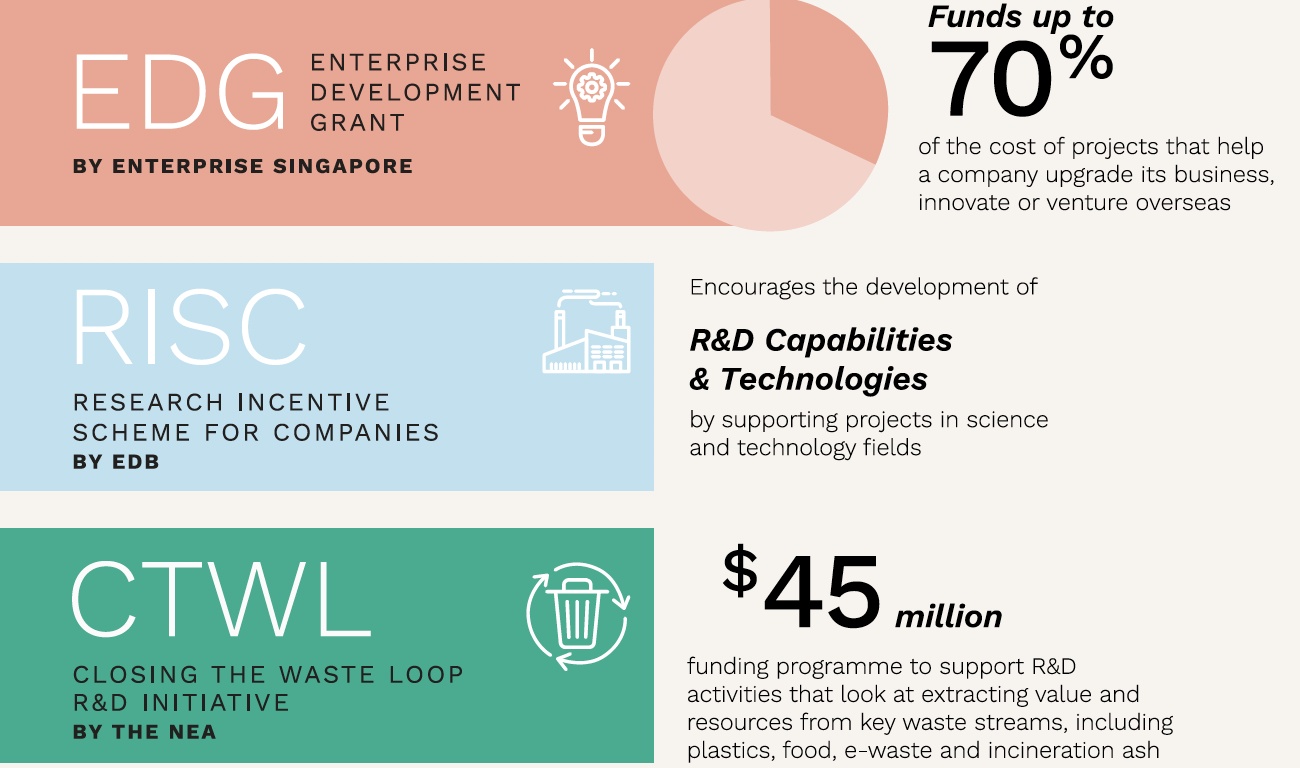

Companies can tap on several funds to reduce the cost of venturing into R&D, or automating their processes.

Related Links

- Enterprise Development Grant (EDG)

- Research Incentive Scheme for Companies (RISC)

- Closing the Waste Loop (CTWL

NO LONGER A MAD RUSH FROM BIN TO BIN

There is no longer a need for a two-men collection crew, running from one recycling bin to the next, and having to push the recycling bins to the truck to be emptied. Now, a truck driver can complete the whole operation from the comfort of his truck cabin, thanks to a side loader.

The side loader has a robotic lifting arm attached to the side of the truck. With simple button clicks and the use of a joystick, the driver can lift and empty the recycling bins into the truck.

Supported by the Singapore Economic Development Board (EDB), this has helped waste management firms like 800Super become more manpower-lean, while improving the working conditions of its staff.

STRATEGY 2 DRIVE WIDESPREAD ADOPTION OF TECHNOLOGY

To encourage the adoption of technology, we focus on three areas:

- Identify technologies to be used on a wider scale

- Establish partnerships for technology exchanges

- Leverage platforms such as the Whole-of-Government Business Grants Portal to provide a technology repository for ease of technology adoption, and Technology Connect Sessions to link the technology providers to service buyers

In order to boost the productivity of Jewel Changi Airport, robots developed by Lionsbot International will be deployed to help with cleaning and waste collection. The robot Leopull helps cleaners by transporting waste carts around Jewel Changi Airport, freeing cleaners up to complete other tasks Photo: Lionsbot International Pte Ltd

In order to boost the productivity of Jewel Changi Airport, robots developed by Lionsbot International will be deployed to help with cleaning and waste collection. The robot Leopull helps cleaners by transporting waste carts around Jewel Changi Airport, freeing cleaners up to complete other tasks Photo: Lionsbot International Pte Ltd

If we want to create a leaner, more elderly-friendly and productive industry, we need to change the way we currently clean spaces and manage waste.

Job redesign is the way forward. The ES Job Redesign Initiative was a joint collaboration between the NEA and Workforce Singapore (WSG), supported by the Environmental Management Association of Singapore (EMAS) and Waste Management and Recycling Association of Singapore (WMRAS). It provided a list of solutions that companies were able to adopt easily, as well as a grant that they could tap on.

The NEA also launched a $30 million Productivity Solutions Grant (PSG) that funds the adoption of commercially available and proven ES technologies, including equipment and digital solutions that raise productivity. It is open to both small and medium-sized enterprises (SMEs) and multinational corporations.

ITM FOCUS 2: Jobs and skills

While technology makes jobs easier, it is also crucial to improve the skills of workers to take on higher-value jobs within the industry. The overall goal is to do more with less – reducing manpower needs through better infrastructure and building design, as well as promoting a “self-serve” mindset where people clean up after themselves.

There are three strategies to achieve these goals:

STRATEGY 1 - MODERATE MANPOWER DEMAND

Everyone plays an important part in minimising the need for cleaning and waste management services. This can be done through simple acts of clearing trays after meals at hawker centres and food courts, or reducing the waste we throw away.

The load of ES workers can be lightened through the following measures:

- Design buildings that enable cleaning and waste collection to be done faster, easier and with fewer workers

- Encourage Singaporeans to keep their surroundings clean through ongoing programmes such as the Keep Singapore Clean Movement, Tray Return initiative and the Daily Cleaning at Ministry of Education (MOE) schools

- Promote the habit of reducing, reusing and recycling

STRATEGY 2 - SUSTAINABLE MANPOWER SUPPLY

As we aim to reduce manpower in the industry, there is still a need to ensure a steady stream of workers for the future.

Senior Minister of State for the Environment and Water Resources, Dr Amy Khor, with recipients of the Certificate of Excellence at the ES Workforce Day in November 2018

Senior Minister of State for the Environment and Water Resources, Dr Amy Khor, with recipients of the Certificate of Excellence at the ES Workforce Day in November 2018

We look to improve on six areas:

- Redesign jobs and adopt automation and assistive technology to reduce the physical demands of the job. This will make the work less strenuous for older employees and reduce the total number of workers needed

- Focus on attracting mid-career switches, senior workers, women returning to the workforce and fresh school leavers

- Improve the industry’s image

- Strengthen human resource policies and practices

- Facilitate internship opportunities

- Tap on National Jobs Bank to connect employers with suitable candidates

The NEA is working with WSG, the industry and solution providers to encourage companies on these fronts. For instance, they have organised appreciation events for ES professionals to recognise their commitment and excellence in their work. They also collaborated with Institutes of Higher Learning (IHLs) to attract the younger generation to the industry, such as by increasing internship opportunities.

STRATEGY 3 - SKILLED AND RESILIENT WORKFORCE

Every worker should be given the opportunity to learn new skills and grow in their jobs. Four possible ways to do so are:

- Create a Skills Framework for ES together with SkillsFuture Singapore (SSG), WSG and industry stakeholders

- Develop apprenticeship and scholarship programmes to attract and retain talent, especially at Associate Professionals and Technicians (APT) and Professionals, Managers and Executives (PME) levels

- Facilitate Pre-Employment Training (PET) and Continuing Education and Training (CET) Programmes together with IHLs, and the expansion of PET and CET offerings

- Review the Singapore Workforce Skills Qualifications (WSQ) modules to ensure that they are still relevant to the industry, particularly for rank and file workers

In 2018, Republic Polytechnic launched a new Part-Time Diploma in Applied Science (ES and Management), which is a Work-Study Programme. This diploma course provides opportunities for participants to deepen their skills and knowledge needed for a career in the ES industry, especially in operational roles from Operations Executives to Hazardous Waste Specialists.

More PET and CET programmes will be gradually put in place to address the skills and training needs of the industry.

Mr Koh Kheng Huat enrolled in the SkillsFuture Work - Study Programme leading to a Part-Time Diploma in Applied Science (ES and Management) by Republic Polytechnic in 2019. The course will prepare him for his job at PV Vacuum Engineering Pte Ltd, a company providing pneumatic waste conveyance system services, by teaching him project management skills and imparting knowledge on environmental operations and environmental sustainability. Photo: PV Vacuum Engineering Pte Ltd

Mr Koh Kheng Huat enrolled in the SkillsFuture Work - Study Programme leading to a Part-Time Diploma in Applied Science (ES and Management) by Republic Polytechnic in 2019. The course will prepare him for his job at PV Vacuum Engineering Pte Ltd, a company providing pneumatic waste conveyance system services, by teaching him project management skills and imparting knowledge on environmental operations and environmental sustainability. Photo: PV Vacuum Engineering Pte Ltd

NOT JUST A LOW-SKILLED INDUSTRY

At local SME Biomax Green Pte Ltd, a dedicated team of professionals leverage advanced biotechnology to develop innovative solutions that improve and diversify the company’s services and offerings. The company specialises in solutions that convert organic waste into high-grade organic fertiliser through the use of digesters and enzymes, which were developed by biotechnology research specialists. The company also employs a qualified team of sales and operations managers to engage local and international clients, and manage projects from around the world.

Biomax laboratory Photo: Biomax Green Pte Ltd

Biomax laboratory Photo: Biomax Green Pte Ltd

As the environmental impact of plastic waste takes the spotlight, Plaspulp Union offers an efficient plastic treatment solution. Ms Jade Loh (pictured), works at Plaspulp Union as an Operations Manager, where she and her team explore recycling solutions for complicated waste materials. Using advanced technology and automation, plastic waste is segregated and processed faster, ensuring a better quality output.

Ms Jade Loh, Operations Manager at Plaspulp Union, explores recycling solutions for waste materials. Photo: SSG

Ms Jade Loh, Operations Manager at Plaspulp Union, explores recycling solutions for waste materials. Photo: SSG

SembWaste Pte Ltd, one of Singapore’s Public Waste Collectors, has adopted a Smart Waste Collection System (SWCS). This system leverages sensor technology to detect the capacity of waste in compactor bins and uses this information to plan vehicle routing and scheduling to optimise resources. This improves productivity, while the use of technology provides higher-skilled jobs in waste collection.

SembWaste waste collection crew uses a smart device to receive waste collection jobs from SembWaste’s Command Centre, where waste capacity levels in compactor bin centres are remotely monitored

SembWaste waste collection crew uses a smart device to receive waste collection jobs from SembWaste’s Command Centre, where waste capacity levels in compactor bin centres are remotely monitored

ITM FOCUS 3 - Productivity

To transform the industry, service buyers have to get involved. By relooking their procurement practices, they can facilitate innovation, productivity and technology adoption.

One way is to shift towards performance or outcome-based contracts, which specify the service outcomes or performance standards required. This is unlike the traditional headcount based approach to procurement, which states the number of workers required. Another way is to have a longer contract period that allows companies to make returns on their investments in technology.

We are also looking at ways to better optimise land use and create additional spaces to raise land productivity. These include housing various recycling activities under one roof, in the form of a multi-storied development, and reusing our closed landfills.

SINGAPORE’S FIRST MULTI-STOREY RECYCLING FACILITY

Slated to be launched in 2021, the Multi- Storey Recycling Facility (MSRF) will create space to house recyclers handling different forms of waste streams like metals, e-waste, paper and plastics under one roof. The colocation of these recyclers will support the circular economy approach by promoting synergies amongst them.

Developed by JTC, and designed in consultation with the NEA and the industry, the facility will offer industrialists heavy production floor loading, high ceiling and wide column span, replicating a land-based operating environment in a high-rise setting. In addition, shared green spaces and facilities will be provided for greater community interaction.

The MSRF will be located next to JTC’s TimMac @ Kranji. The MSRF will facilitate the re-use of wastes and by-products from the metals, machinery and timber industries that will be housed within TimMac @ Kranji.

Artist’s impression of the multi-storey recycling facility. Photo: JTC

Artist’s impression of the multi-storey recycling facility. Photo: JTC

SARIMBUN RECYCLING PARK

Tucked away in the north-western corner of Singapore that was once the Lim Chu Kang Dumping Ground is Sarimbun Recycling Park (SRP).

Set up in 1995 to give recycling a boost, it is home to over 10 recycling plants that handle a quarter of the country’s recycling. There, construction waste is turned into recycled material for roads and buildings, horticultural waste into compost and charcoal, and scrap plastic into plastic pellets that can then be reused to manufacture new products.

The NEA is now looking at using SRP once more to push the recycling sector forward.

In 2017, it launched a study into the strength and stability of the ground, soil and ground water conditions at SRP. The NEA is currently working with other Government agencies to explore redeveloping and intensifying the land use at SRP so that it can continue to support the circular economy approach of closing our waste loops through recycling in Singapore.

ITM FOCUS 4 - Internationalisation

Limited by Singapore’s small market size, companies can only grow by venturing overseas. Expanding across borders gives companies the impetus and opportunity to gain new capabilities and expertise that will help them to be globally competitive. There are three strategies to achieve this.

STRATEGY 1: ENHANCE MARKET ACCESS

Breaking into a new market is difficult, especially when in a foreign land and up against household names. To get the word out about what we have to offer, the NEA will be collaborating with its overseas counterparts, as well as participating in international projects.

We will also continue to widen the horizons of our ES companies and trade associations, by supporting their learning trips overseas where they can be exposed to the world’s most innovative technologies.

Through international platforms and events that the NEA regularly organises, such as the CleanEnviro Summit Singapore, we also help them link up with the international audience. The key objective of this event is to serve as a platform for local companies to showcase their products, solutions and services to international buyers, distributors and collaborators. It also offers in-depth discussions, roundtables and sharing of best practices. The fourth edition in 2018, held in conjunction with the World Cities Summit and the Singapore International Water Week, attracted over 24,000 visitors from more than 120 countries and regions, with over 1,100 participating companies.

STRATEGY 2: GROW CAPABILITIES TO CAPTURE OVERSEAS MARKETS

Innovation and internationalisation go hand in hand. To be globally competitive, companies cannot survive with “me-too” products that do not top their competitors’ offerings.

We support companies that venture overseas by developing their capabilities in identified growth areas with high market potential. Solutions developed can also be adopted by other countries with the same aspirations for a clean and liveable environment as us.

STRATEGY 3 SCALE UP AND OFFER INTEGRATED SOLUTIONS

To be a world leader in providing solutions to environmental challenges, we need the whole industry to work together to put ideas into action. By working with other industry sectors in the Built Environment Cluster, the NEA aims to develop integrated solutions, tapping on the unique capabilities of each sector, for city planning and development projects overseas.

Enablers

Strengthening trade associations to support transformation

We look to our trade associations such as WMRAS and EMAS to spearhead industrywide collaboration, and support them through various initiatives.

For instance, Enterprise Singapore’s Local Enterprise and Association Development (LEAD) programme supports WMRAS and EMAS in initiatives that build up their core capabilities to better support industry transformation in their subsectors. They include internships for students, which create a pipeline of talent for the industry, and overseas mission trips to help enterprises hunt for opportunities abroad and source for new technologies.

Artist’s impression of Hong Kong’s first Integrated Waste Management Facility (IWMF). Singapore company

Keppel Infrastructure Holdings Pte Ltd, and China Harbour Engineering Company Limited, through their respective

wholly owned subsidiaries, Keppel Seghers Hong Kong Limited and Zhen Hua Engineering Co. Ltd., clinched the

S$5.3 billion project to design, build and operate Hong Kong’s first IWMF for municipal solid waste. The IWMF will

include a 3,000 tonnes/day Waste-To-Energy (WTE) plant that is capable of generating approximately 480 million

kWh of net electricity/year, as well as a 200 tonnes/day mechanical treatment plant for sorting and recycling

glass, plastics and metals. Photo: Keppel Infrastructure

Artist’s impression of Hong Kong’s first Integrated Waste Management Facility (IWMF). Singapore company

Keppel Infrastructure Holdings Pte Ltd, and China Harbour Engineering Company Limited, through their respective

wholly owned subsidiaries, Keppel Seghers Hong Kong Limited and Zhen Hua Engineering Co. Ltd., clinched the

S$5.3 billion project to design, build and operate Hong Kong’s first IWMF for municipal solid waste. The IWMF will

include a 3,000 tonnes/day Waste-To-Energy (WTE) plant that is capable of generating approximately 480 million

kWh of net electricity/year, as well as a 200 tonnes/day mechanical treatment plant for sorting and recycling

glass, plastics and metals. Photo: Keppel Infrastructure

LOCAL R&D FINDS OPPORTUNITIES OVERSEAS

A microbial treatment developed to break down food waste at low operating temperature has produced odourless fertiliser.

Westcom Solutions collaborated with researchers from the A-STAR Institute of Chemical and Engineering Sciences to develop the treatment. Test-bedded in JTC’s Pandan Loop Industrial Estate, it works under a lower temperature than current food waste conversion processes.

The company has exported the solution overseas, and 70% of its revenue is now generated from overseas sales.

Other channels to help companies capture opportunities overseas include the Environmental & Water Technology Centre of Innovation (EWTCOI), which is supported by Enterprise Singapore. It aids companies in developing and commercialising technology to meet market demand.

For instance, EWTCOI helped company Regentech bring the technology to convert unwanted coconut husks into biochar to Singapore. This solution was subsequently exported to Thailand.

A Westcom Solutions researcher conducting research

to develop microbes to break down food waste at a low

operating temperature. Photo: Westcom Solutions Pte Ltd

A Westcom Solutions researcher conducting research

to develop microbes to break down food waste at a low

operating temperature. Photo: Westcom Solutions Pte Ltd

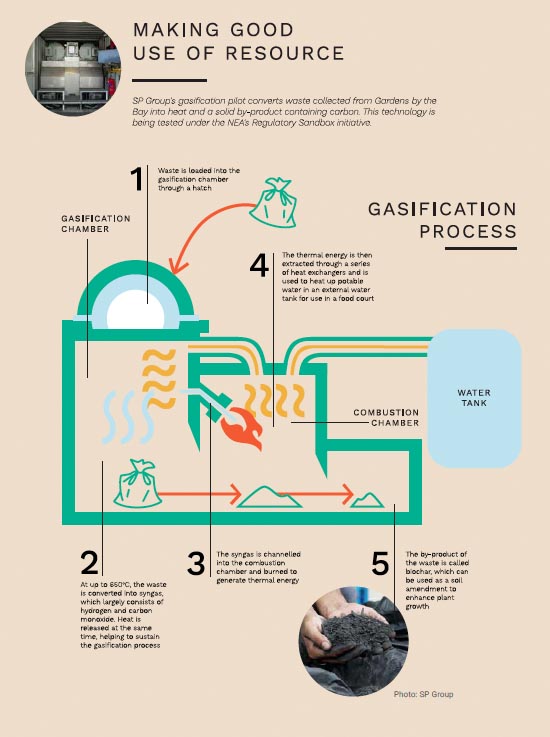

Using regulations and standards to transform the industry

As with any new disruptive technology, regulation can sometimes hold back new ideas from taking flight. Hence the NEA launched a Regulatory Sandbox for ES in July 2018. This allows companies to trial innovative ES-related technologies and solutions without compromising the environment, public health and safety.

Regulations that previously prohibited the trial of a solution can be relaxed for a fixed duration and within certain parameters. This helps companies develop innovations that have the potential to become industry game-changers. Examples of technology on trial in the Regulatory Sandbox include a waste management solution that demonstrates circularity within premises.

Improving safety, quality and productivity of the ES industry is a critical concern. The Singapore Standardisation Programme, administered by Enterprise Singapore, addresses the issue by setting standards for adoption by companies. For example, the new pneumatic waste conveyance system standard reduces manpower requirements and enhances the hygiene and safety of waste collection.

Moving forward, Singapore will continue to participate in the International Organisation for Standardisation (ISO) Technical Committees. New areas where Singapore will be involved in are waste collection and transportation management, as well as solid recovered fuels and circular economy. By setting and meeting international standards, we will help smoothen the path for local companies looking to export their products and services overseas.

Establishment of demonstration sites

The INnovating CUrating Better Automation and Technologies for Environmental Services (INCUBATE) partnership was set up to bring the public and private sectors together to prototype, pilot and profile solutions. We currently have 18 partners.

Our partners are working with the NEA to explore the adoption of innovative solutions such as smart compactors, and the use of in-sink grinders with on-site food waste treatment systems to increase operational efficiency.

RECYCLE FOOD WASTE, AND SAVE MONEY

Several food waste recycling machines have been tested through the INCUBATE programme and helped to close the food waste loop, diverted waste away from our only landfill and resulted in cost savings.

Nanyang Polytechnic and Republic Polytechnic have used food waste digesters at their school food court while Changi Airport Group has deployed food waste digesters at all its terminals for tenants to use.

Meanwhile, City Developments Limited launched a pilot project at the Le Grove Serviced Residences where food waste is ground through an in-sink grinder. It is then conveyed automatically to a food waste treatment system, where it is converted into compost.

With the wheels of transformation in motion, our goal is to have a competitive and attractive environment services industry by 2025. By harnessing the power of technology and automation, we will create better jobs that are less labourious, and more highly skilled. Through these, we will move closer to our vision of an ES industry that is vibrant, sustainable and professional.

https://www.towardszerowaste.sg/zero-waste-masterplan/chapter5/