Packaging

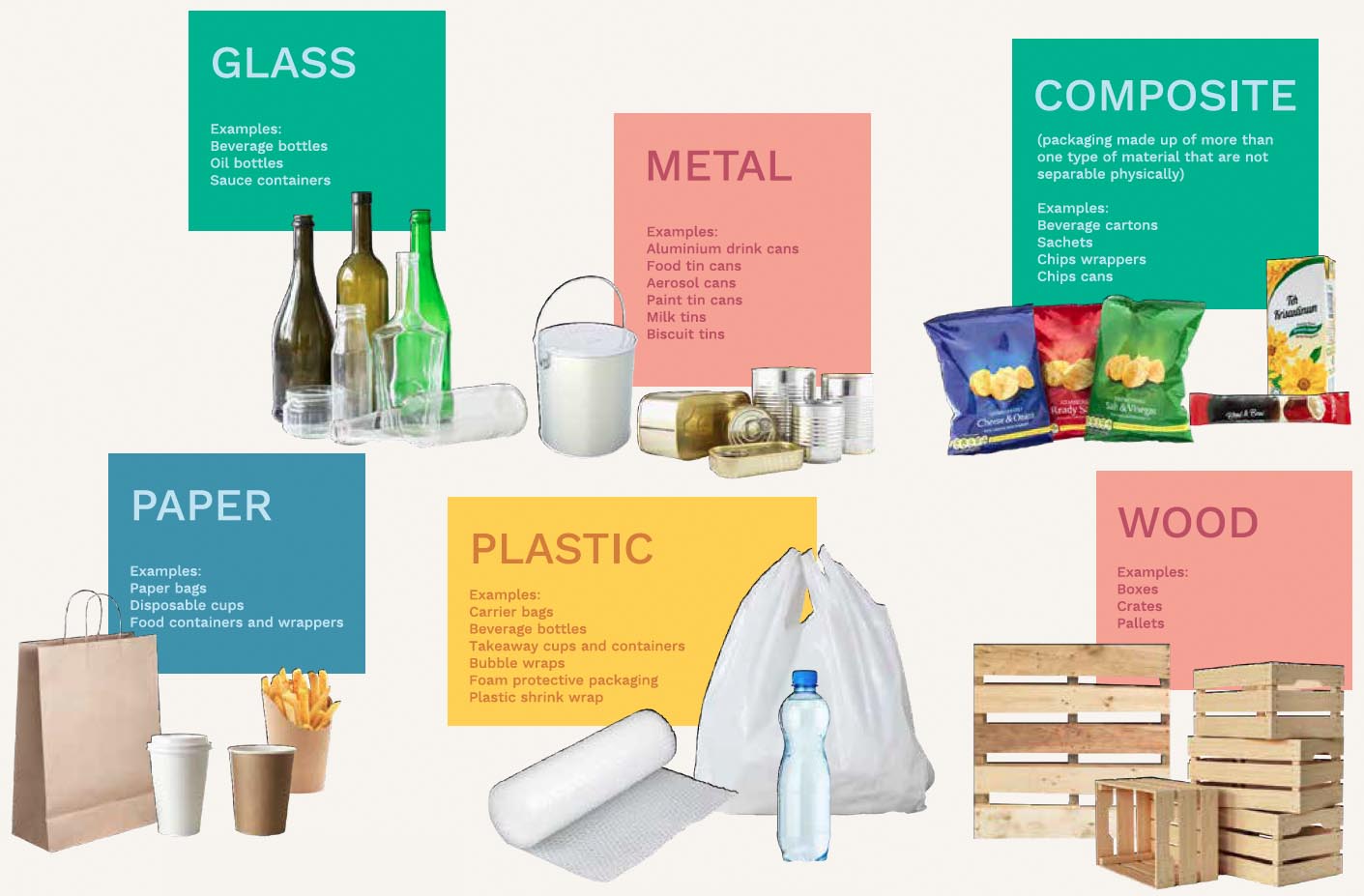

Packaging can be made from any material and is used to contain, protect, handle, deliver or present goods. A large proportion of our domestic waste is packaging waste.

In 2018, about one-third of domestic waste disposed of consisted of packaging waste. Approximately 55% of the packaging waste was plastic packaging, whilst 25% was paper packaging. The remaining 20% was made up of other types of packaging materials, such as metal and glass.

As packaging is so common yet hardly reused, we need to find ways to reduce and consume them more sustainably.

ENCOURAGING SUSTAINABLE CONSUMPTION OF PACKAGING

The Singapore Packaging Agreement

The Singapore Packaging Agreement (SPA) is a joint initiative started in 2007 by the Government, industry and non-governmental organisations (NGOs) to reduce packaging waste. Since its inception, more than 200 organisations in Singapore have worked together to cut down on packaging waste. As of 2019, they have cumulatively reduced about 54,000 tonnes of packaging waste, resulting in estimated packaging material cost savings of $130 million for locally consumed products.

The NEA will continue to work with the industry to develop its capabilities in adopting the circular economy approach through sustainable production and design, and establishing best practices in the 3Rs (reduce, reuse and recycle).

Supporting ground-up movements

We are supporting ground-up initiatives through funding support. One such initiative was Zero Waste SG’s Bring Your Own (BYO) campaign, supported by the Call for Ideas Fund, aimed at encouraging consumers to use reusable bags and containers when they buy takeaway food, beverages and groceries. Since 2017, more than 400 retail outlets have joined the campaign, providing incentives to customers who bring their own reusables. This has saved approximately two million pieces of plastic disposables and packaging. Leveraging the success of BYO, the NEA supported Zero Waste SG with the Partnership Fund to further develop the campaign in 2019 into Bring Your Own Bag (BYOB) to focus on reducing disposable plastic bag usage.

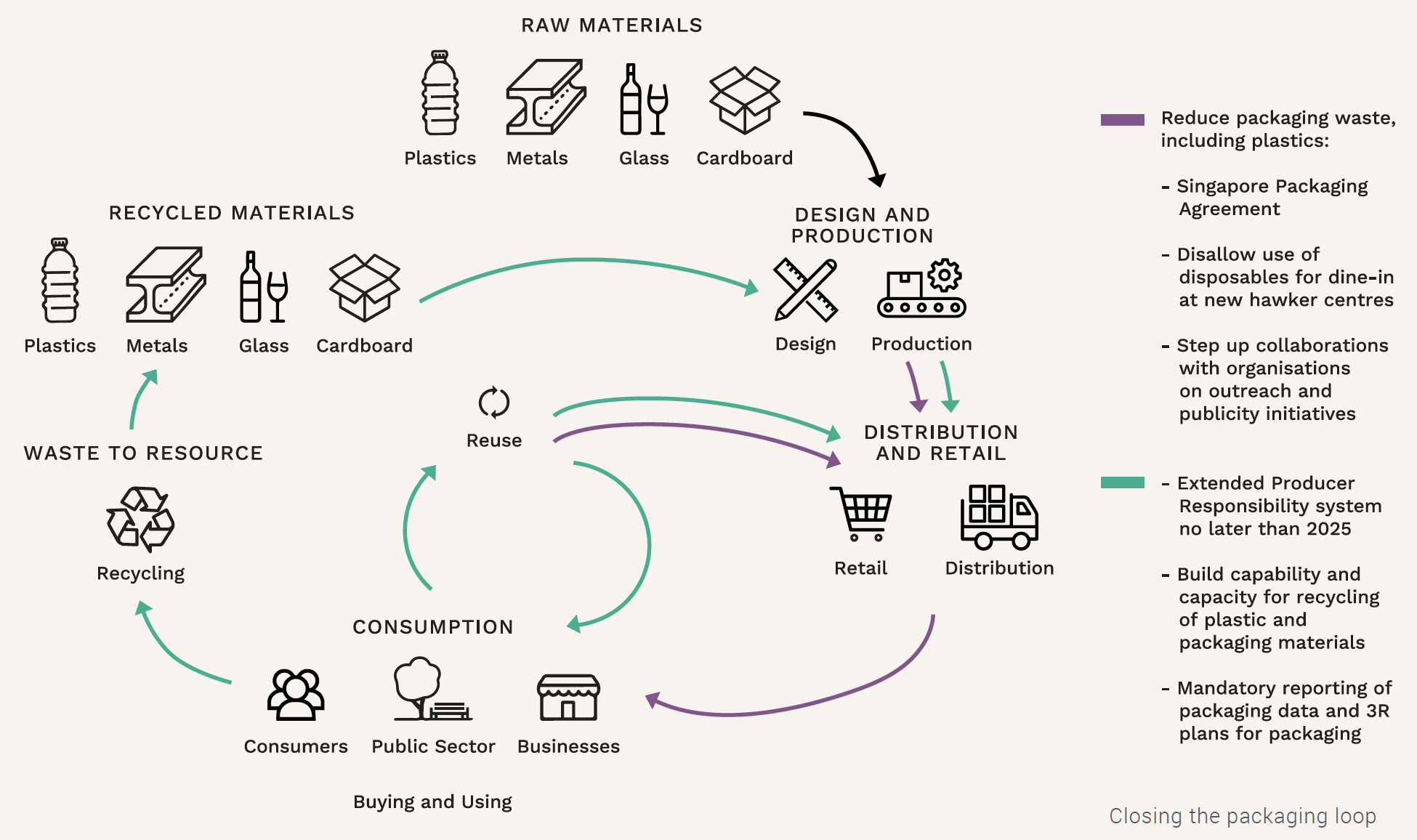

THE PACKAGING WASTE MANAGEMENT ROADMAP

Packaging is not all bad. It extends the shelf life of food and protects new products from damage during transportation. However, the problem is excessive packaging. That is why we are introducing measures to encourage companies to adopt sustainable production by reducing packaging upstream.

Mandatory reporting of packaging data and 3R plans for packaging will be introduced in 2020 and legislated under the Resource Sustainability Act. This builds on an existing mandatory waste reporting framework for large malls and hotels, which will also be expanded to all large industrial and commercial premises, including large convention and exhibition centres, in 2020. For the mandatory packaging reporting framework, for a start, producers of packaged products and supermarkets with an annual turnover of more than $10 million will be required to report data on packaging that they put on the market and their 3R plans for packaging.

The mandatory packaging reporting framework will also lay the foundation for an EPR framework for managing packaging waste, including plastics. This ensures producers are responsible for the collection and recycling of the materials they use to package their products. We are currently studying the approach, and will hold consultations with the industry. The aim is to have the EPR system for packaging waste management in place no later than 2025.

CLOSING THE PLASTICS LOOP

The use of plastics is prevalent in our daily lives – many of our beverage bottles, takeaway food containers, and grocery bags are made of plastics. While plastics can be useful, they are often used in excess and discarded in large amounts.

Plastic has become an issue of significant concern globally as countries re-examine how to sustainably manage their plastic waste. In Singapore, we incinerate all our general waste, minimising the amount of plastic that ends up as litter both on land and in the oceans. At the same time, with the drive towards circular economy to replace the “take-make-dispose” linear economy, and the push to reduce industrial carbon emissions, we have observed an increasing interest among the industry to explore more advanced technology to close the plastics loop.

Take for example, the adoption of chemical recycling to turn plastic into feedstock or fuel. Apart from the current prevalent technology of using mechanical recycling to recycle plastics, chemical recycling technology involves converting separated or mixed plastics back into pyrolysis oil, naphtha, methanol and syngas. These products can either be converted back into building blocks which can be used to make new plastic products, or converted into fuel to replace fossil fuel sources. In particular, there are opportunities for mixed or dirty plastics, which cannot be recycled currently through mechanical means, to be recycled. As a petrochemical hub, Singapore is well-placed to harness this new growth area to close the plastics loop.

The Government will work with stakeholders from various industry sectors to explore how these technologies can be applied to Singapore such that it is both environmentally and economically sustainable. We will also continue to engage stakeholders to holistically assess the benefits of other measures to manage plastic waste better. For instance, imposing a charge for single-use plastic bags may divert demand to paper or bio-degradable bags, which may not be more resource-efficient from a lifecycle perspective. This is because the production and disposal of all materials have some degree of environmental impact. Therefore, we will work on managing excessive consumption of all types of packaging and disposables.

Through the adoption of a circular economy approach to close the resource loops of food waste, e-waste and packaging waste, including plastics, we can move closer towards our Zero Waste future, where both households and the industry consume less, waste less and recycle more.